Jinan Transon CNC Equipment Co., Ltd.

S I N C E 2 0 1 0

1325 1530 Plasma CNC Cutting Machine

Plasma cutting was originally developed for the thermal cutting of materials which were unsuitable for flame cutting, such as high alloy steels or Aluminum. Today, the process is also used for the economical cutting of thin, low alloyed steels.

WHAT IS PLASMA? THE FOURTH STATE OF MATTER

One common description of plasma is to describe it as the fourth state of matter. We normally think of the three states of matter as solid, liquid and gas. For a common element, water, these three states are ice, water and steam. The difference between these states relates to their energy levels. When we add energy in the form of heat to ice, the ice melts and forms water. When we add more energy, the water vaporizes into hydrogen and oxygen, in the form of steam. By adding more energy to steam these gases become ionized. This ionization process causes the gas to become electrically conductive. This electrically conductive, ionized gas is called a plasma.

HOW PLASMA CUTS THROUGH METAL

The plasma cutting process, as used in the cutting of electrically conductive metals, utilizes this electrically conductive gas to transfer energy from an electrical power source through a plasma cutting torch to the material being cut.

The basic plasma arc cutting system consists of a power supply, an arc starting circuit and a torch. These system components provide the electrical energy, ionization capability and process control that is necessary to produce high quality, highly productive cuts on a variety of different materials.

The power supply is a constant current DC power source. The open circuit voltage is typically in the range of 240 to 400 VDC. The output current (amperage) of the power supply determines the speed and cut thickness capability of the system. The main function of the power supply is to provide the correct energy to maintain the plasma arc after ionization.

The arc starting circuit is a high frequency generator circuit that produces an AC voltage of 5,000 to 10,000 volts at approximately 2 megahertz. This voltage is used to create a high intensity arc inside the torch to ionize the gas, thereby producing the plasma.

The Torch serves as the holder for the consumable especially nozzle and electrode, and provides cooling (either gas or water) to these parts. The nozzle and electrode constrict and maintain the plasma jet.

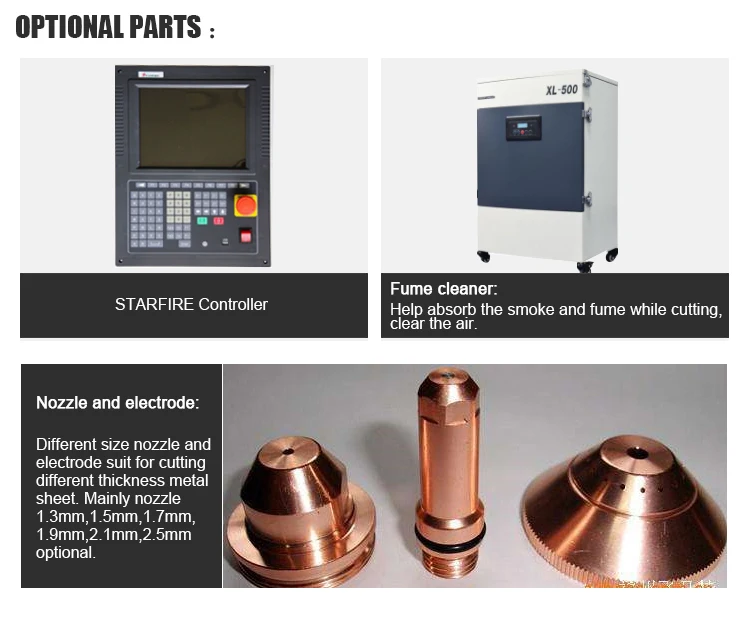

Features:

1. This machine adopts thick square tube wholly welding; the machine body adopts shaking preventing technical disposal, with the features of firm, shape retention, and high rigidity.

2. Reasonable platform design, the flat table adopts 10mm precision process steel plate install on the machine table, and then install precision process cast iron cover to protect the vertical steel, to prevent the steel plate affected by high strength flame. The level difference of whole double-deck platform remains in 0-1.5mm.

3. Reasonable pitch leaks design, to make the work piece and other fragments slide to the sides of the knife rack, safe and convenient to use.

4. This machine adopts Japanese Panasonic servo motor and high precision gear wheel. The noise is low, and the machine runs steadily.

5. This machine adopts Start control system made in Sino-US joint venture and Germany design Software FASTCAM with auto material saving function

6. The machine adopts American Cut-Master power source (power 40A/120A/200A) together with high sensitive arc pressure adjuster. Self-adjusting to choose the best distance between plasma head and work piece automatically in order to ensure cutting accuracy

7. Good reasonable design and high immaculate surface's work piece make the machine best choice for different thickness material and heterotypic sheet cutting

Parameters:

Model | TSP1325/ TSP1530 |

Working Area(X*Y) | 1300mm×2500mm/ 1500x3000mm |

Cutting thickness | (40A)0.5-10mm (120A)3-16mm (200A)3-25mm |

Work speed | 0-50000mm/min |

Cutting Speed | 0-8000mm/min |

Cutting thickness | 3--16mm/120A |

Plasma Generator | China HUAYUAN LGK |

Document Transmission Form | USB Interface |

Working Form | THC (Torch Height Controller) |

Working Voltage | 3-Phase 380V |

Power | 8.5KW—10.5KW |

G.W. | 980KGS |

Remarks | Configured with Taiwan servo speed reducing device |

Machine details:

Application:

Application Materials:

Stainless steel, steel, iron,carbon steel, brass, copper, aluminum alloy, Titanium, etc

Application Industry:

Sheet metal, kitchenware, components, decorations industry,Ship Building,Construction Equipment,Transport Equipment,Aerospace Industry,Bridge Building,

Military Industrial,Wind Power, Structural Steel, Boiler Containers, Agriculture Machinery, Chassis Electrical Cabinets, Elevator Manufacturers,Textile Machinery,etc.

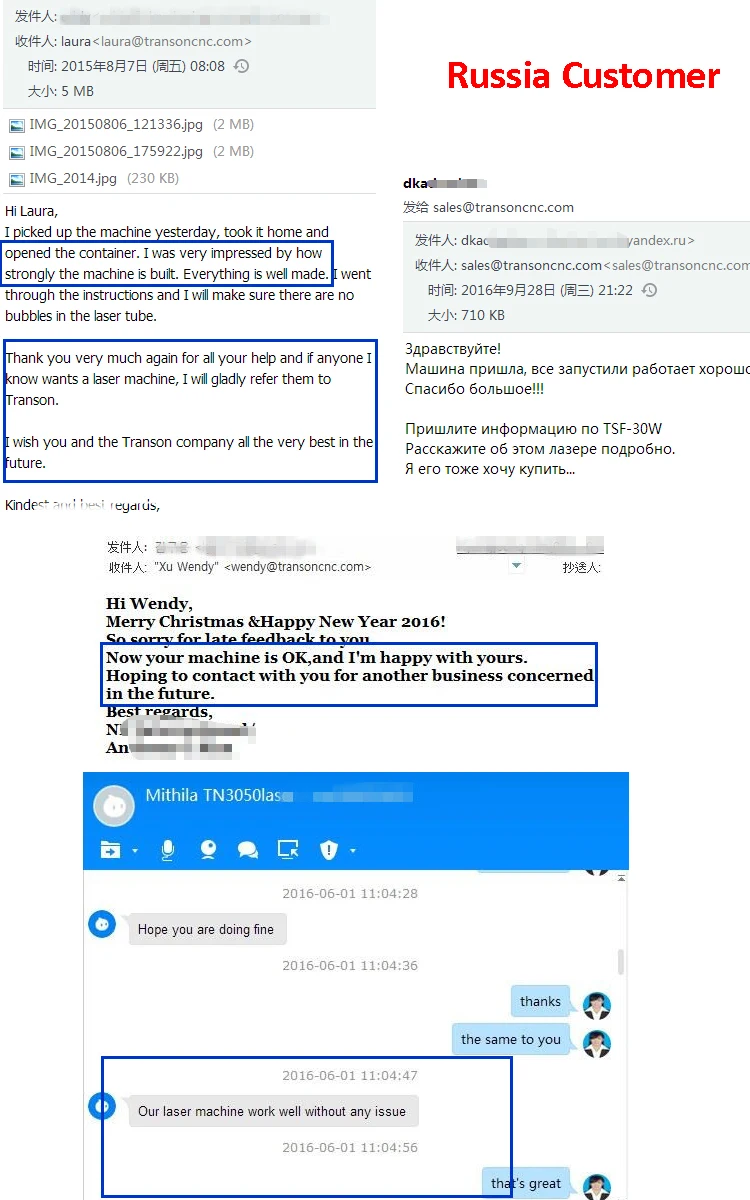

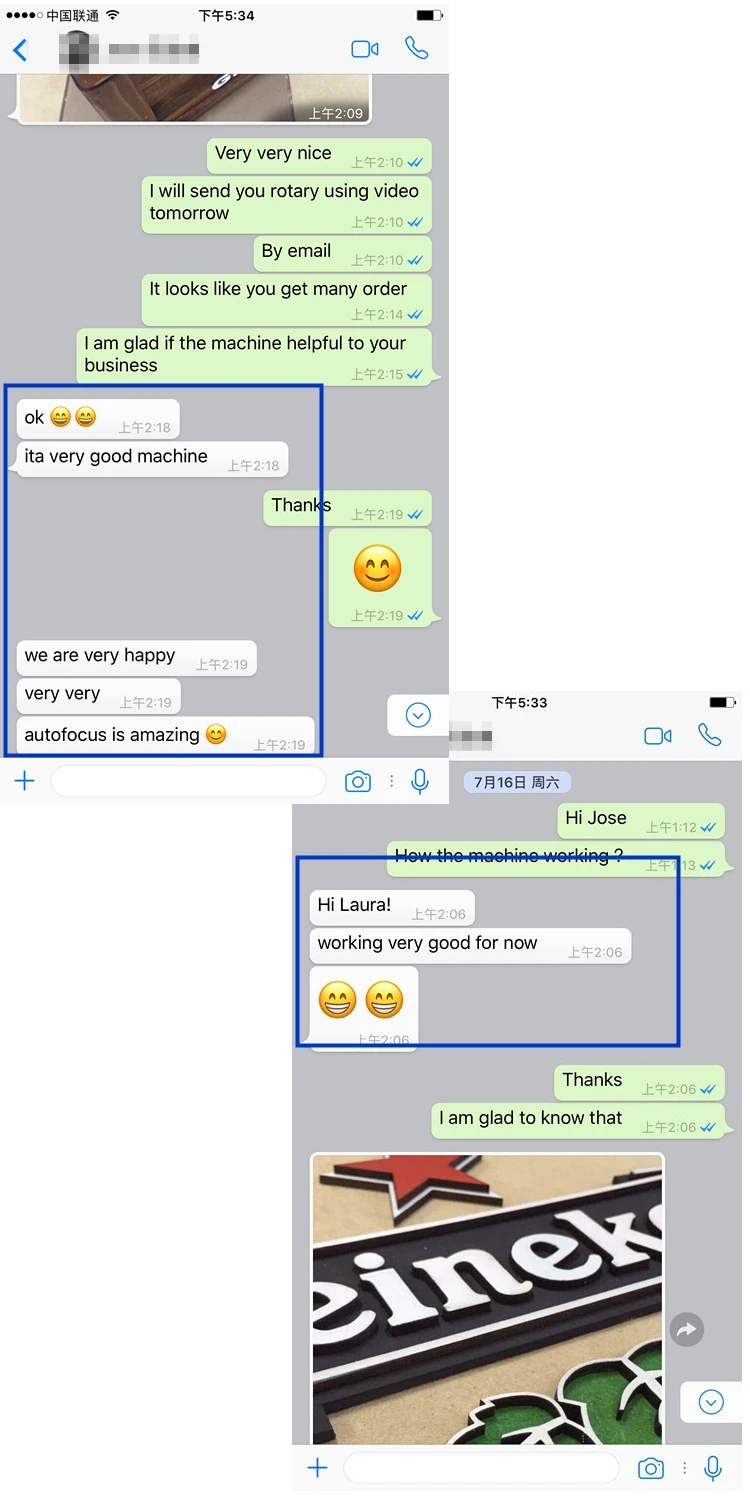

Jinan Transon CNC Equipment Co., Ltd is an integrated CNC automation equipment manufacturer with ability of research and development, design and production. Our products include fiber laser marking machine, CO2 laser marking machine, CO2 laser engraving and cutting machine, cnc router and cnc plasma cutter.

Transon CNC has won an excellent reputation in the golbal market. We are cooperating with many well-known companies all over 100 counties, including Turkey, United Kingdom, United States, Korea, russia, Peru, Chile, etc. We alos maintain a friendly long-term cooperation with domestic laser research institues all over the years.

FAQ:

Q1: Are you a factory or trading company?

A: We are a manufacturer found in 2010.

Q2: Where are you located? How can we visit you?

A: We locates in Jinan city of Shandong, in the north of China. Please tell us your airplane number or train number, we will arrange sales and driver pick you up to factory.

Q3: How can I choose suitable machine?

A: Please communicate with us via inquiry or email, we can guide you. Please kindly tell us:

1).What work you will do?

2). What work table size you will need?

Q4: What's your payment terms? Delivery time and MOQ?

A: We accept T/T(bank transfer), L/C, Paypal, West union, Paypal, etc.

Usually we need 30% as deposit, balance paid before shipment.

Delivery Time: 7-10 days after payment

MOQ: 1set

Q5: If I bought a machine, how could you make it safe while shipping.

A: We have a professional package suitable for oversea transportation. Machine will be fixed well in the case.

Q6: What's your quality control system?

A: All machines with CE and FDA certificate. Our QC department will do full test of each machine after finish, and send you test video and photos for confirm.

Q7: What's your after-sales service?

A: 1) Warranty 1 year for whole machine. Fiber laser source 3 years.

2) Engineers available service machinery overseas

3) 7X24hours online support and whole life maintenance.

Q8: If I don't know how to use the machine, can you teach me?

A: 1) There is a U disc send together with the machine including machine user manual and software user manual .

2) Online (Skype, Whatsapp, Wechat, Phone)

3) Remote desktop software (Team viewer)

4) Demo Video

Q9:This is my first time buy machine from China, how i buy machine from you?

A:Choose suitable machine through talking with our seller manager → Pay to us→ manufacture and testing machine(about 3-5 workdays) →shipping to you

If you have any other questions, please write email to us or call us, we will reply you ASAP.

Copyright © 2025 Jinan Transon CNC Equipment Co., Ltd | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist