Jinan Transon CNC Equipment Co., Ltd.

S I N C E 2 0 1 0

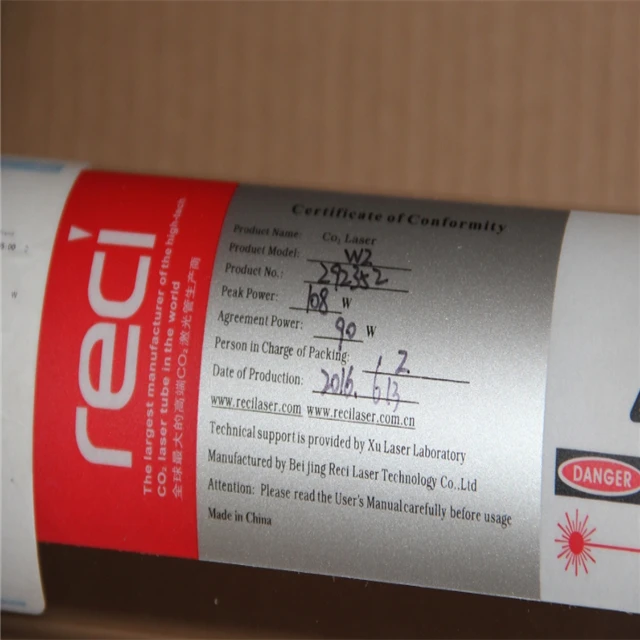

Co2 Laser Glass Tube For Laser Engraving Cutting Marking Machine

Brand model : W1/ W2/ W4/ W6 /W8

Quality standard: 75-90W/90-100W/ 100-130W/ 130-150W/ 150-180W

1. Installation Requirement

Make sure to follow the operation instruction of model W1 as shown in the illustration. The dedicated power P12 should be equipped. The positive pole of laser tube is in high voltage (the ignition voltage is 19kv). It may cause the following consequence when it is failed to follow the instruction: Arcing; the inner tube will be punctured by electricity and may cause water leakage.

2. Operation conditions

Water cooling: using purified water; 2 to 5 liter/minute; water temperature: 10℃-40℃.

The operating environment: temperature 2-40℃; Humidity 10-60%.

The working current: test current is 29mA. Maximum working current is 29mA. The running current must be kept below 27mA. The life span can reach 8,000 hours if the current is kept below 25mA. The ammeter must be connected to the negative electrode of laser tube.

When it is working under over-high current for long term, the negative pole will appearlight yellow and the life span will be shortened rapidly.

To protect dust from going into the insulation sheath, please wrap it with plastic film.

3. Working Performance

Cutting function.

Engraving function: Very good. When the working current is 4mA and the tube is in the state of preionization, the laser can be used for high-frequency impulse engraving.

4. Key Notes

Do not clean the exterior surface of the output widow mirror with tools such as tampon; otherwise the output power will be seriously affected. The followings are the designated methods to clean up pollution in the exterior surface of window mirror:

1) When the mirror is polluted, do not turn on the laser.

2) Blow the mirror surface sideways with an air blower.

3) Spray the pure alcohol on the mirror surface with sprayer.

4) Turn on the laser after the alcohol gets fully volatilized.

5) If the methods above don't work effectively, it is necessary to ask for the professional to use tampon with alcohol to clean the mirror surface from middle to edge. The best solution is to prevent the window from being polluted.

Attention: it is forbidden to clean the mirror with acetone.

The screws in the front and back ends of the laser tube are not allowed to be moved, otherwise the output power will be declined, even the tube will be scrapped.

Put the acryl 300mm far away from output mirror, when testing its laser spot.

5. Safety

The laser beam is invisible light. Please wear protective glasses when debugging the laser. The positive pole is in high voltage. Pay attention to the security marks.

6. Storage and Transportation Requirement

Pour out cooling fluid in the event of storage and transportation, and cover the output terminal with a dust-proof plastic bag. The storage environment is 2-40℃, and the requested humidity is 10-60%. Pack the laser as in the original way.

Important notes: it is requested to use adhesive tape to cement the sponge together with laser tube to prevent the tube from vertically sliding during transportation. The sponge in the side of output mirror must be 70 mm beyond it, and the sponge in the side of reflecting mirror must be 50 mm wider.

Tubes operated in wrong way are not guaranteed by Manufacturer.

Copyright © 2026 Jinan Transon CNC Equipment Co., Ltd | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist